General Stamping Company

309 State Route 94, Columbia, NJ 07832

309 State Route 94, Columbia, NJ 07832

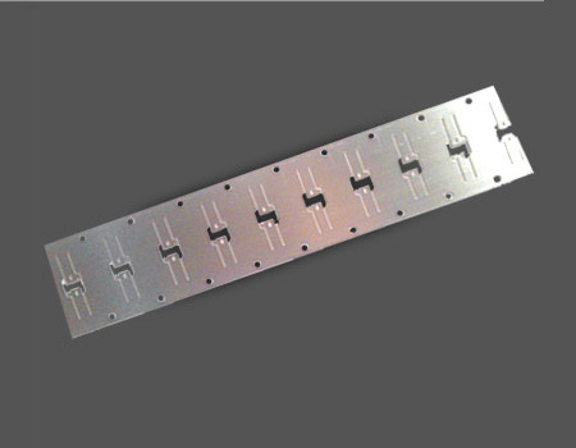

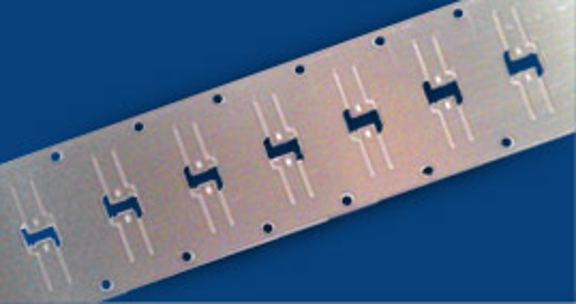

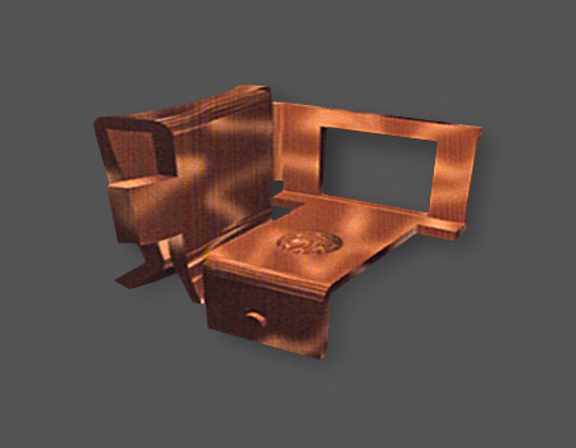

Our company has been in business since 1965. We are a contract manufacturer that produces tools based on our customer’s print specs. Our production department can run jobs as small as 1,000 pcs up to millions of pcs daily. We have a fully staffed engineering department and in house tool room that designs, builds and repairs all of our progressive dies using Wire EDM technology. Dependent on the alloy, we can stamp anywhere from .001” to .200” thick while maintaining tolerances to ± .0005”. We excel in blanking dies, forming dies as well as wire forming/4 slide. Some of the metals that we stamp: Glass sealing alloys such as Kovar or Alloy 42, Copper Alloys, Brass, Aluminum, Stainless Steel (300 and 400 series), Phosbronze, Cold Rolled Steel, Nickel, clads, bi-metals and precious metals. We also have a diverse supply chain for raw material, heat treating and plating that include rack, barrel, and reel to reel plating. Industries Served: Electronic Components, Connectors, Telecommunications, Fasteners, Resistors, Capacitors/Semiconductors, Military, Wire Forms/ 4 Slide, Washers, Aerospace, Automotive, Switches/Relays, Hardware, Medical, Industrial, Reel to Reel Components

More Business Info

- BBB Rating

- Hours

- Regular Hours

Mon - Fri: Sat - Sun Closed - Services/Products

- Contract Manufacturing, Progressive Dies, Metal Stampings

- Metal Stampings

- Contract Manufacturing

- Progressive Dies

- Payment method

- check, no credit cards

- Accreditation

ISO 9001:2015 Certified

ISO 14001:2015 Certified

- Other Link

- Category

- Metal Stamping

Suggest an Edit