Lowrance Machine Shop

13510 E Hardy Rd, Houston, TX 77039

13510 E Hardy Rd, Houston, TX 77039

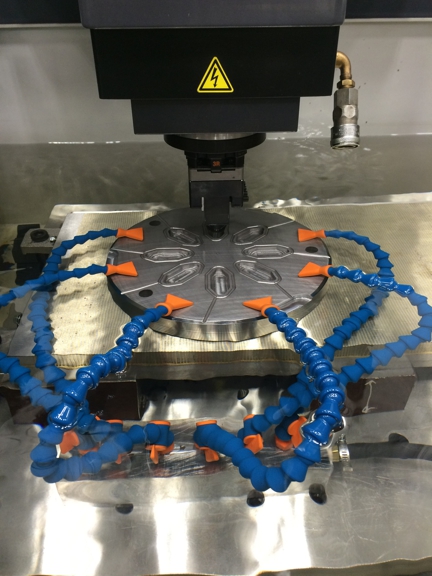

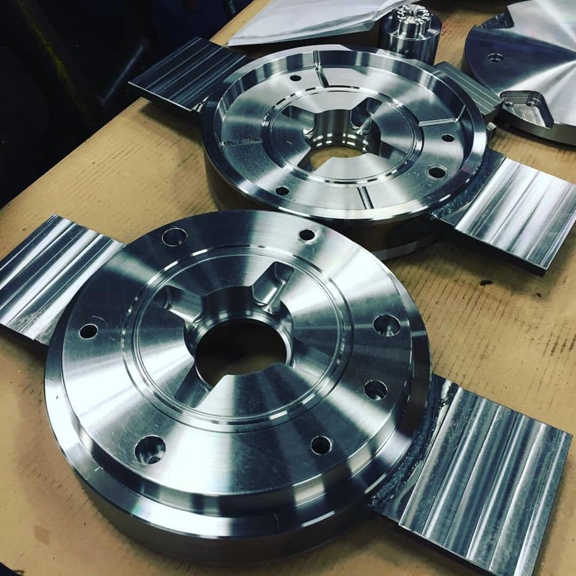

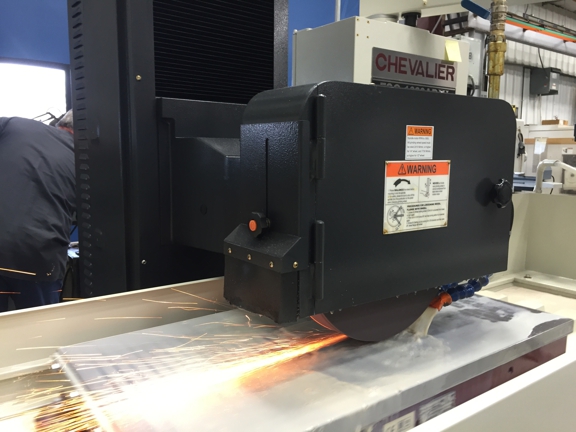

CNC & MANUAL MACHINING Our Lathe and Mill operations are the backbone of our company and accomplished by our well-trained and experienced machinists. We are able to provide our customers with a complete and cost-effective supply solution. CNC (Computer Numerical Control) machines are used to manufacture parts by utilizing computers to precisely machine material into desired forms. Tasks like repairs or single part manufacturing can sometimes be done faster on a manual machine. We have a wide assortment of CNC and Manual machines designed for long-term accuracy and superior surface finishes, bore sizes and lengths. Visit our website to see our size capabilities. CUSTOM MOLDS Lowrance Machine has been providing resources in the engineering, reverse engineering and machining of molds since 1964. We specialize in: Rubber Molds (Compression, Transfer, Injection), Mold Engineering, Reverse Part Engineering, Open Pour Molds, Mold Repair, Mold Inserts, Plastic Molds (Injection). We build molds for engineered elastomeric shapes, custom plastic shapes, and custom seals - including S-Seals, T-Seals, D-Rings, O-Rings, Rod Seals, Piston Seals, Wipers, Hammer Unions, Energizer Seals, Front/Rear Seals, Top Seals, BOP Seals and many more. ENGINEERED COMPONENTS Our team understands that providing quality components results in measurable benefits to our customers’ bottom line. We utilize the newest software packages for control and automation of our processes, all the while being continuously monitored by our experienced professionals. Common components include: Custom Flanges with Inlayed Ring Grooves, RTJ Seal Rings, Spacer Spools, Piston Rods, End Rings, Top Seats, Cylinder Liners, Retracting Pistons/Cylinders, Bearing Housings, Bushings, Shaft Seals and many other engineered products. NON-STANDARD SPECIAL FASTENERS We can manufacture Non-Standard Special Fasteners to your drawings and specifications. No drawing, no problem! Send us a sample part and we will reverse manufacture the sample provided. Specializing in Non-Standard: Bonnet Bolts, Single and Double-Ended Studs, All-Thread Studs, Nuts, Heavy Hex Bolts, Socket Head Screws, Engineered Specialty Items. INDUSTRIAL REPAIR Our Team has the knowledge base that comes not only from training but decades of experience working on virtually every type of industrial repair. Our can-do attitude will ensure that you are back up sooner and running more reliably. Common repairs include: shaft repairs, thread repairs, broken bolt removal, and large/small part rebuilds. QUALITY MANAGEMENT SYSTEM Lowrance Machine recognizes that having a Quality Management System is required to meet our customers demanding needs. We are ISO 9001-2008 certified. Our success is measured by performance, evaluation, review, and a Kaizen Program of Continuous Improvement. Additionally, we use a Calibration Tracking Software. OTHER CAPABILITIES Lowrance Machine also offers the following services/capabilities: EDM (Sinker) High Speed CNC Electrode Machining Press Rebuilds: Slab side, Post, and Transfer Hardness Testing (HBW, HRC, HRB) Non-Destructive Thickness Measurements Engraving Drilling and Tapping Sawing Welding (Tig and Mig) OTHER TURNKEY SOLUTIONS Lowrance Machine partners with suppliers that offer the following services/capabilities: Heat Treating Welding and Cladding Metallurgical and Mechanical Testing Deep Hole Drilling and Honing Premium Threading NDT (Non-Destructive Testing) Coating and Plating (all types) Electropolishing, Passivation and Mechanical Polishing CONTACT US TODAY FOR MORE INFORMATION WWW.LOWRANCEMACHINE.COM

More Business Info

Quality, Service, Experience

- Business History

- PROVIDING COMPLETE QUALITY SERVICE YOU CAN COUNT ON - FOR THREE GENERATIONS Lowrance Machine is a family owned company founded by Jesse J. Lowrance, Jr. in 1964. The value of hard work and commitment were ingrained in Jesse at an early age when he started his machining career in Houston. In addition to his full time job he worked late nights and weekends out of a garage to support his family. Over years of dedication, he crafted a successful reputation and was able to open the doors of Lowrance Machine. The current President of Lowrance Machine is Ron Lowrance, Jesse’s son. Ron has paved the way as a respected and innovative business owner. He has used his experience, expertise and passion for success that he learned from his father and has passed these along to his sons, Chris Lowrance and Matt Lowrance. Together, Ron, Chris and Matt use the experience of three generations to guide Lowrance Machine through today’s ever changing market place.

- Hours

- Regular Hours

Mon - Thu: Fri: - Logo

- Services/Products

- CNC and Manual Machining, Custom Molds (Rubber, Plastic, Open Pour), Engineered Components, Non-Standard Special Fasteners, Industrial Repair, Quality Management System, EDM (Sinker), Press Rebuilds, Hardness Testing, Engraving, Thickness Measurements.

- Payment method

- all major credit cards, check, amex, visa, mastercard, discover

- Location

- Directions via Google Maps link https://www.google.com/maps?ll=29.910382,-95.374003&z=15&t=m&hl=en-US&gl=US&mapclient=embed&cid=8678555159530977925

- Neighborhood

- Aldine Gardens

- Associations

- ISO 9001:2008 Certified GHMA (Greater Houston Manufacturing Association) AMBA (American Mold Builders Association) EPG (Energy Polymer Group)

- Other Link

- Social Links

- Categories

- Rubber Products, Industrial Equipment & Supplies, Machine Shops, Plastics-Finished-Wholesale & Manufacturers

Suggest an Edit